PRODUCTS

As a leader in automation solutions, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

AUTOMATIC DEBURRING MACHINE

Price: ContactThe automatic bavia machine is widely used in production factories, is an important equipment to improve the efficiency of production activities, whose performance is superior to manual labor.

-

AUTOMATIC SORTING MACHINE

Price: ContactAutomatic sorting machine is an important factor to improve logistics distribution efficiency, which performance is superior to manual labor.

-

MOTOR ASSEMBLY AND INSPECTION MACHINE

Price: ContactSmall motors used in electronic devices or cars are complex and high technology. Therefore, the machines and lines used to assemble these motors must not only meet very high requirements to ensure quality and output, but also have to meet other strict requirements, including machine speed.

The machine is capable of automatically supplying, assembling and inspecting products after assembly, labeling, packing… depending on the requirements and investment budget of the customers.

All of these machine are designed in 3D, simulating and optimizing movements before manufacturing to ensure accuracy and reliable operation.

-

-

PRODUCT PACKAGING LINE

Price: ContactAutomatic packaging line is a combination of equipment and machinery operating automatically without human intervention. Lines perform tasks such as weighing, feeding, packing and labeling products in some stage or final stage of the production process. The purpose of this process is to ensure accurate dosing, save costs and increase product aesthetics.

-

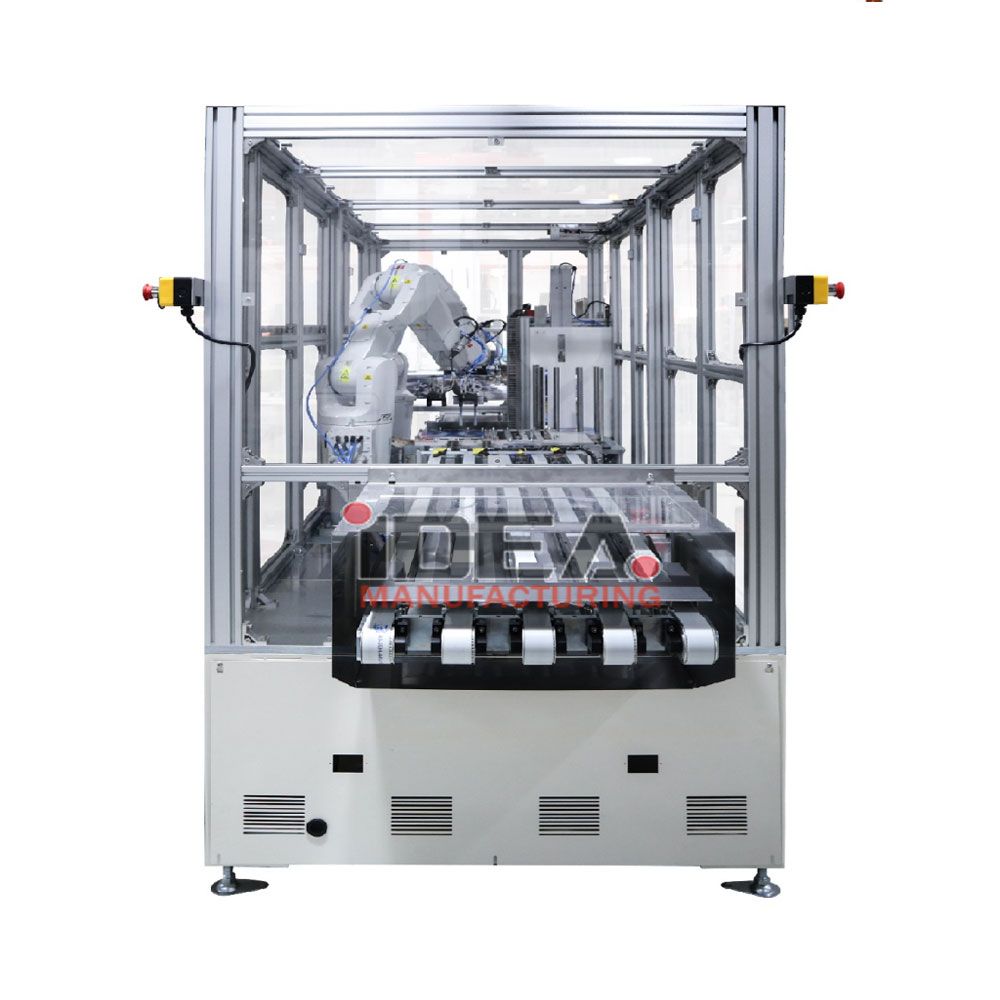

PRODUCTS ASSEMBLY MACHINE

Price: ContactProduct assembly machines and assembly lines play a large role in high-volume OEM or product assembly plants. The assembly machine is capable of automatically supplying, assembling and inspecting parts, assembling details into clusters or assembling into a finished product. We can design and manufacture automatic and semi-automatic assembly machines for many different products, with different degrees of automation, which supply many large FDI corporations in Vietnam.