DESIGN AND MANUFACTURE JIGS

Jig is essential equipment in the process of manufacturing or mechanical processing. jig helps to fix the product for assembly, inspection, welding… In addition, it also helps to determine the relative position of the workpiece to the cutting tools, to keep it tight and ensure accuracy when machining.

Using jig while processing and assembling a large of high-precision parts can helps to increase accuracy and productivity in production and manufacturing.

jig helps determine the specific positions of the standard part to perform current operation or the next operations, locate the part to be machining and other equipment on machines during machining quickly and exactly.

Also plays a role in guiding drilling, cutting, reaming…

Has many different designs, shapes, and functions, with each design style having different models, to meet all the unique needs of the business.

Helps improve the production capacity of difficult and highly complex specific parts.

Also contributes to the growth of new advanced technologies compared to tools and machines.

Contributes to reduce the budget of capital contribution and labor.

Increase the quality of processed products

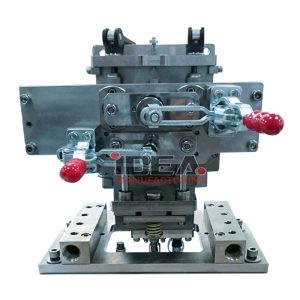

Design and manufacture jigs at IDEA:

With many years of experience in the field of design and manufacturing of jigs. IDEA always provides clients with the most optimal jig designs with guaranteed precision and technology. We can manufacture according to the requirements and designs of clients such as Toyota, Mitsubishi, Honda…. In addition, we will design jigs based on clients’ specific ideas or requirements to match the products they are manufacturing. The jigs we currently provide are drilling jig, milling jig, assembly jig, inspection jig, welding jig, quick assembly jig…

We are proud to be the leading company in Vietnam specializing in supplying and designing all kinds of jig for processing and manufacturing. With the experience of working with more than 150 partners, 99% of which come from the strictest markets such as Japan and the US, the products that come to clients are always the most perfect.

Jigs that IDEA designed and manufacture for clients:

1-Clamp jig.

2-Bending jig.

3-Welding jig.

4-Assembly jig.

5-Inspection jig.

6-Machining jig.

Please contact us if you have a need to design and manufacture jigs.

PRODUCTS

As a leader in automation solutions, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

ASSEMBLY JIG

Price: ContactAssembly JIG is used in assembling parts together to link product assemblies. JIG helps products achieve high accuracy and ensure technical requirements. Usually, assembly JIG is used to clamp product components for assembly, to position the parts to be assembled, to create profiles for welding, pressing, and air compression in the production process.

-

BENDING JIG

Price: ContactIn order to meet the needs of bending and forming products in production, this bending JIG plays a very important role. This JIG helps to fix and hold products before bending, and is also used for the assembly of specific parts together, for the purpose of providing high efficiency in the most practical way in the manufacturing.

-

CLAMP JIG

Price: ContactClamping JIG is a type of JIG that are widely used in machining. With the role of positioning and clamping. This JIG will optimize the machining process and increase productivity through shortening the clamping time.

It uses a clamping cylinder and a pneumatic system that is directly connected to the CNC machine, through the programming system, the machine part will be clamped for processing. The machining time of a typical operation will be significantly reduced.

-

INSPECTION JIG

Price: ContactInspection JIG is used for measuring and checking, helping to determine product parameters to compare with output standards and customer requirements. An inspection JIG is designed and manufactured with the ultimate solution for precise and clear results from measurements. This helps the inspection department quickly determine whether the product meets the requirements or not. The inspection process takes place with high accuracy and productivity to help reduce product costs and improve competitiveness for businesses.

-

MACHINING JIG

Price: ContactMachining JIG contributes to a higher degree of mechanization and automation of precision mechanical manufacturing. On machine tools, in order to cut, it is necessary to fix the parts. Therefore, JIG is an essential technological equipment in the manufacturing on metal cutting machines. It is necessary to have a JIG that meets the positioning and clamping standards.

-

WELDING JIG

Price: ContactWelding JIG serves in the field of welding, such as JIG in car body manufacturing, aircraft, oil and gas, and heavy industry. JIG helps determine the position of the workpiece relative to the welding tool, which holds the product firmly in the position to be processed and ensures accuracy, safety.

With high accuracy, welding JIG helps determine the position between workpieces and different welding and cutting tools. JIG helps to fix the position to avoid the surrounding external forces affecting the production process.