-

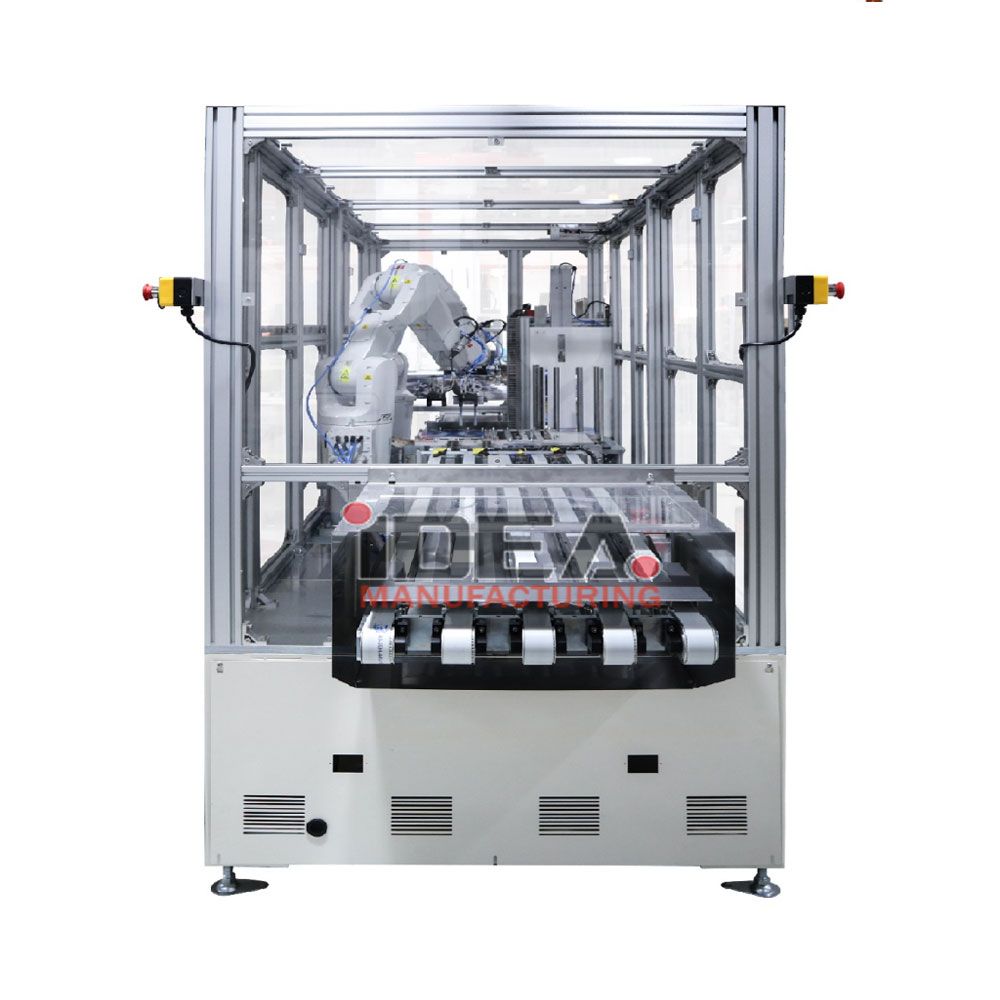

DIMENSION INSPECTION MACHINE

Price: ContactThe machine is not only capable of automatically inspection the dimensions of parts and products, but also can inspect for deformations and defects of the product. This helps to increase productivity and product quality, creating the reputation of manufacturers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

ENGINE ASSEMBLY MACHINE

Price: ContactEngines such as aircraft engines, cars, construction machines, and agro-forestry machines are complex and have numerous of parts that need to be assembled. With the demand for output as well as quality, the automation in this field has developed greatly.

-

GEARBOX ASSEMBLY MACHINE

Price: ContactThe gearbox is an important part, it combines with the engine to control the movement. The gearbox has very high requirements for assembly and alignment accuracy during assemblies. Like engines, in the past most gearboxes were assembled manually, but automated assembly methods are increasingly used.

As a leader in automation solutions, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

IMPURITY INSPECTION MACHINE

Price: ContactIf impurities exist or penetrate into products, it will cause great harm to manufacturers, especially in the field of food, drink and also in equipment and products requiring high safety. The machine is capable of automatically inspect different types of impurities, depending on the requirements of the customers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

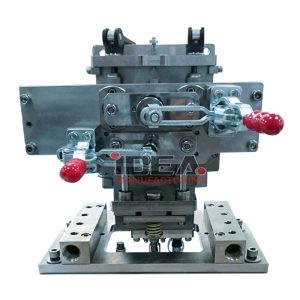

INSPECTION JIG

Price: ContactInspection JIG is used for measuring and checking, helping to determine product parameters to compare with output standards and customer requirements. An inspection JIG is designed and manufactured with the ultimate solution for precise and clear results from measurements. This helps the inspection department quickly determine whether the product meets the requirements or not. The inspection process takes place with high accuracy and productivity to help reduce product costs and improve competitiveness for businesses.

-

MACHINING JIG

Price: ContactMachining JIG contributes to a higher degree of mechanization and automation of precision mechanical manufacturing. On machine tools, in order to cut, it is necessary to fix the parts. Therefore, JIG is an essential technological equipment in the manufacturing on metal cutting machines. It is necessary to have a JIG that meets the positioning and clamping standards.

-

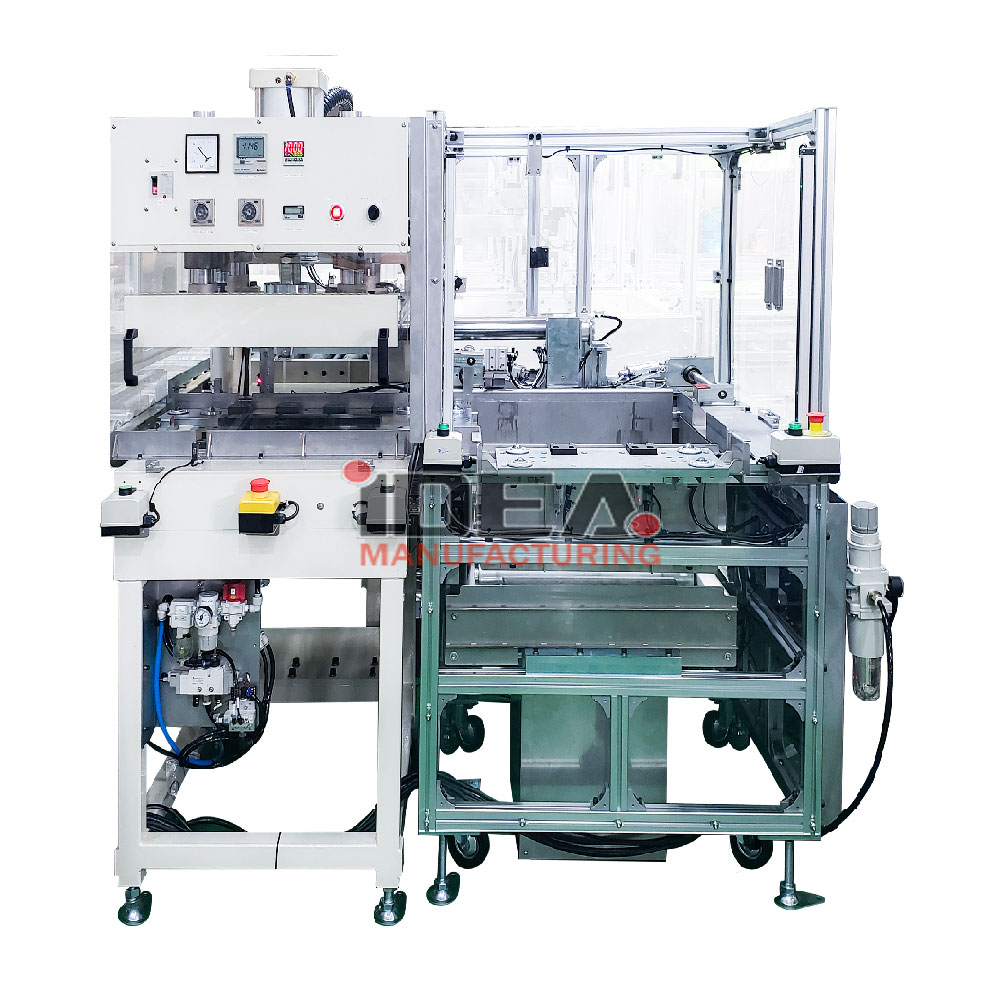

MOTOR ASSEMBLY AND INSPECTION MACHINE

Price: ContactSmall motors used in electronic devices or cars are complex and high technology. Therefore, the machines and lines used to assemble these motors must not only meet very high requirements to ensure quality and output, but also have to meet other strict requirements, including machine speed.

The machine is capable of automatically supplying, assembling and inspecting products after assembly, labeling, packing… depending on the requirements and investment budget of the customers.

All of these machine are designed in 3D, simulating and optimizing movements before manufacturing to ensure accuracy and reliable operation.

-

MOTOR ASSEMBLY MACHINE

Price: ContactMotor assembly machines are consulted, designed, manufactured and assembled by IDEA according to the requirements of each customer.

As a leader in automation solutions and motor assembly machine, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

OEM ASSEMBLY MACHINE

Price: ContactMore and more major brands use OEM from suppliers, OEM production is increasing globally. Therefore, it is necessary to automate the OEM assembly stages to ensure not only the quantity ordered but also the quality stability.

-

PALLET TRANSPORTATION AGV IGR-PTA

Price: ContactThe IGR-PTA automated guided vehicle (AGV) is intelligent answer for human replacement for pallet transportation task during your production process.

With SLAM navigation method, no need to add guide or command objects such as magnet strip on your factory floor. This fully safe AGV will also works friendly in spaces where human are active.

After installation and get training, you will be able to independently program the AGV, customize routes, add AGV, and easily change existing commands with intelligent software.

-

-

PRODUCT PACKAGING LINE

Price: ContactAutomatic packaging line is a combination of equipment and machinery operating automatically without human intervention. Lines perform tasks such as weighing, feeding, packing and labeling products in some stage or final stage of the production process. The purpose of this process is to ensure accurate dosing, save costs and increase product aesthetics.

-

PRODUCTS ASSEMBLY MACHINE

Price: ContactProduct assembly machines and assembly lines play a large role in high-volume OEM or product assembly plants. The assembly machine is capable of automatically supplying, assembling and inspecting parts, assembling details into clusters or assembling into a finished product. We can design and manufacture automatic and semi-automatic assembly machines for many different products, with different degrees of automation, which supply many large FDI corporations in Vietnam.

-

PROFILE INSPECTION MACHINE

Price: ContactThe machine has the ability to automatically inspect all kinds of profiles, deformations, defects of the product caused by previous stages. The system is integrated by modern sensors and cameras to help detect errors immediately, prevent efflux and immediately prevent mass waste that can cause great losses to manufacturers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

QUANTITY INSPECTION MACHINE

Price: ContactThe machine has the ability to automatically inspect the number of products on the line when packing, this helps manufacturers monitor productivity, and commit quantity and volume to consumers. In addition, it also helps to make statistics of productivity by shift, crew, month, quarter quick and in time.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

SORTING ROBOT

Price: ContactThe pick-and-sorter system is used to pick up products from input locations, and perform sorting according to predefined criteria and move products to other locations where is defined in the program.