PRODUCTS

As a leader in automation solutions, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

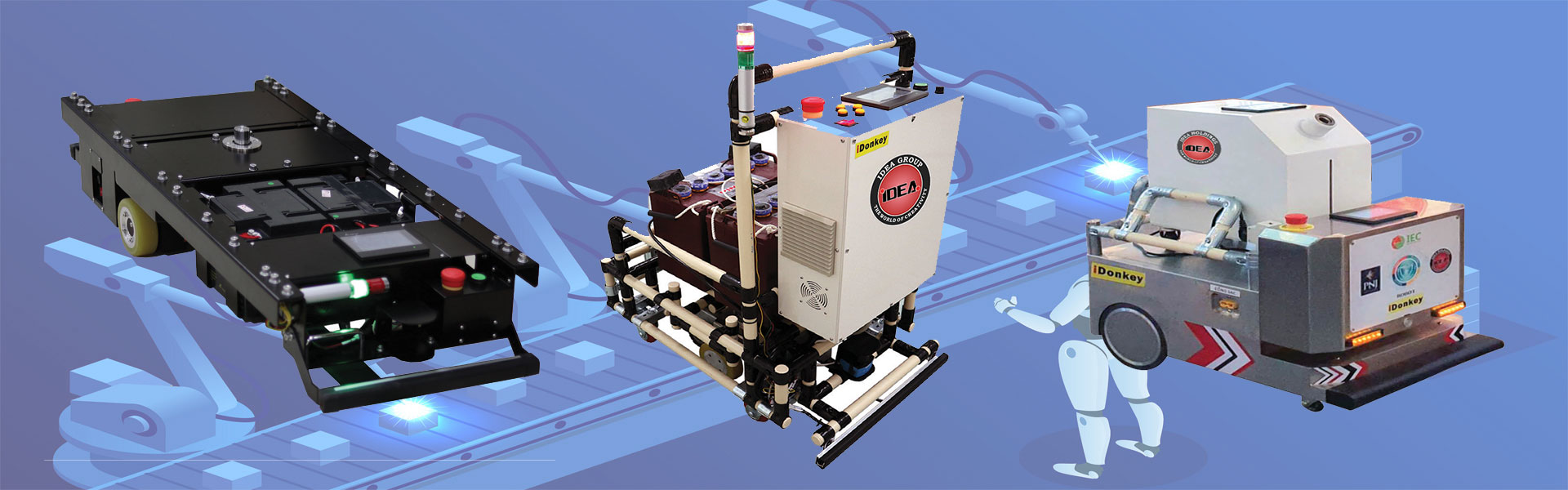

AUTOMATED GUIDED VEHICLES IGR – STA

Price: ContactAutomated Guided Vehicles IGR – STA is a very compact AGV for towing or carrying solutions.With simple modern design, this AGV will meet all of your expectations for various application with most reasonable cost.

-

PALLET TRANSPORTATION AGV IGR-PTA

Price: ContactThe IGR-PTA automated guided vehicle (AGV) is intelligent answer for human replacement for pallet transportation task during your production process.

With SLAM navigation method, no need to add guide or command objects such as magnet strip on your factory floor. This fully safe AGV will also works friendly in spaces where human are active.

After installation and get training, you will be able to independently program the AGV, customize routes, add AGV, and easily change existing commands with intelligent software.

-

ULTRA LOW PROFILE AGV IGR-UPA

Price: ContactThe Ultra Low Profile AGV IGR-UPA series is manufactured with compact size, low substructure and large capacity , that can provide automatic transportation around the plant with appropriate cost.

-

3 AXIS ROBOT

Price: Contact3-axis robot, XYZ robot is a specialized robot with high precision and speed, applied in the industry of manufacturing and assembling electronic components, automobiles and motorcycles such as applying glue to PCB circuits, or applying grease, glue to multi-point positions, difficult to manipulate, complex profiles on motorcycle gearboxes, circuit boards.

-

6 AXIS ROBOT

Price: ContactThe 6 axis robot has a compact and flexible arm suitable for operations such as pick-and-place, precision assembly, parts transportation, and welding. The robot is light in weight and small in size, so it can be placed inside the processing machine, hung on high, and can work in narrow environments.

-

AUTOMATED GUIDED VEHICLES IGR – STA

Price: ContactAutomated Guided Vehicles IGR – STA is a very compact AGV for towing or carrying solutions.With simple modern design, this AGV will meet all of your expectations for various application with most reasonable cost.