PRODUCT INSPECTION MACHINES

1. Increase productivity:

With the population entering the ageing period, labor shortage becomes a social problem. Competition on productivity is getting fiercer because it affects product prices. In addition, because the inspection process is important work with human eyes and senses, only skilled people can undertake it. Automation is the key to make up for this shortage of human resources and reduce defective products.

2. Increase demand for product quality:

Especially in the field of semiconductor industry, car, aviation and other mechanical and electronic products, there is an ongoing trend towards product miniaturization and product refinement. As a result, stricter standards are required for product quality, for which normal inspection has a relatively high error rate and high risk. Automated inspection prevents human errors, which makes it easier to control error rates and also reduces production costs.

3. Benefits of automated inspection:

There are three benefits to automated inspection:

– High speed

– No human error

– Labor saving

Automation solutions of IDEA Technology Corporation:

After many years of experience in contacting and directly operating in the field of Automation with the Japanese and FDI markets, we are proud to have brought to our clients the most complete and optimal solutions in their production and business activities. We supply to the market with over 100 different types of machines each year.

With a team of experienced engineers and experts, especially a large design team, we can design from concept a variety of machines according to the actual requirements of clients. In addition to advising clients on automation solutions in production, we also help clients increase productivity and revenue. We will always accompany clients through solutions. Our products and services are most suitable and optimal with the application of Japanese technology.

PRODUCTS

As a leader in automation solutions, we carry out all processes in automation from consulting, planning to design, production and assembly, and operations support.

-

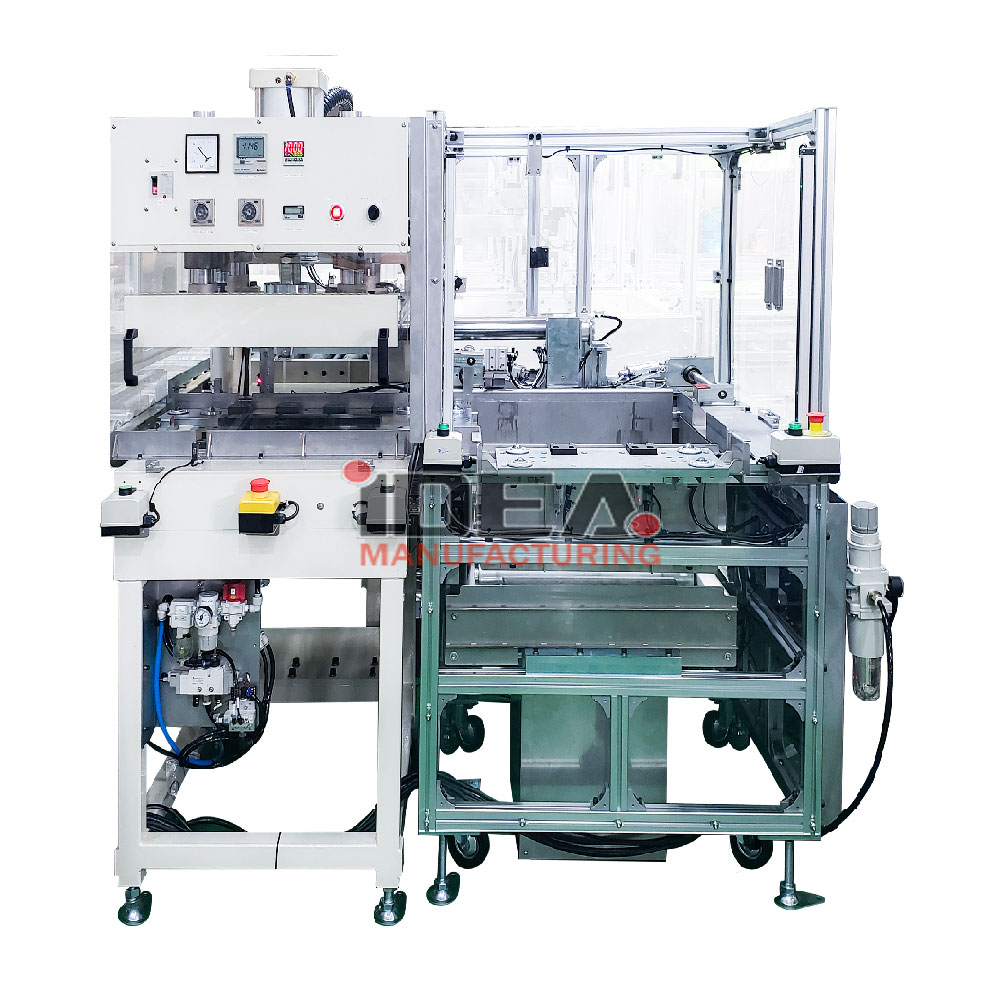

ASSEMBLY INSPECTION MACHINE

Price: ContactThis machine has the ability to automatically inspect the assembly process, helping to detect missing parts or improperly assembled parts. This machine can also be combined with inspection of appearance, impurities and dust to ensure that the assembled product meets quality and safety standards.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

DEFECT INSPECTION MACHINE

Price: ContactDefects are also a serious error, which must be eliminated promptly before moving on to the next stage or before reaching the consumer. The machine is capable of automatically inspection for defects on products by applying modern image processing technology, ensuring high accuracy.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

DIMENSION INSPECTION MACHINE

Price: ContactThe machine is not only capable of automatically inspection the dimensions of parts and products, but also can inspect for deformations and defects of the product. This helps to increase productivity and product quality, creating the reputation of manufacturers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

IMPURITY INSPECTION MACHINE

Price: ContactIf impurities exist or penetrate into products, it will cause great harm to manufacturers, especially in the field of food, drink and also in equipment and products requiring high safety. The machine is capable of automatically inspect different types of impurities, depending on the requirements of the customers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

PROFILE INSPECTION MACHINE

Price: ContactThe machine has the ability to automatically inspect all kinds of profiles, deformations, defects of the product caused by previous stages. The system is integrated by modern sensors and cameras to help detect errors immediately, prevent efflux and immediately prevent mass waste that can cause great losses to manufacturers.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.

-

QUANTITY INSPECTION MACHINE

Price: ContactThe machine has the ability to automatically inspect the number of products on the line when packing, this helps manufacturers monitor productivity, and commit quantity and volume to consumers. In addition, it also helps to make statistics of productivity by shift, crew, month, quarter quick and in time.

All of these devices are designed in 3D, optimally simulating movements before manufacturing to ensure accuracy and reliable operation.