Automation in Machine Manufacturing: The Ultimate 2025 Guide

Automation in machine manufacturing is revolutionizing production lines by enhancing efficiency, ensuring consistency, and accelerating industrial improvement. As companies worldwide strive to remain competitive, the integration of automated solutions into manufacturing processes has become more than just a trend—it’s a strategic necessity. From robotic arms to AI-driven systems, automation continues to redefine how factories operate in an ever-evolving industrial landscape.

The Role of Automation in Modern Machine Manufacturing

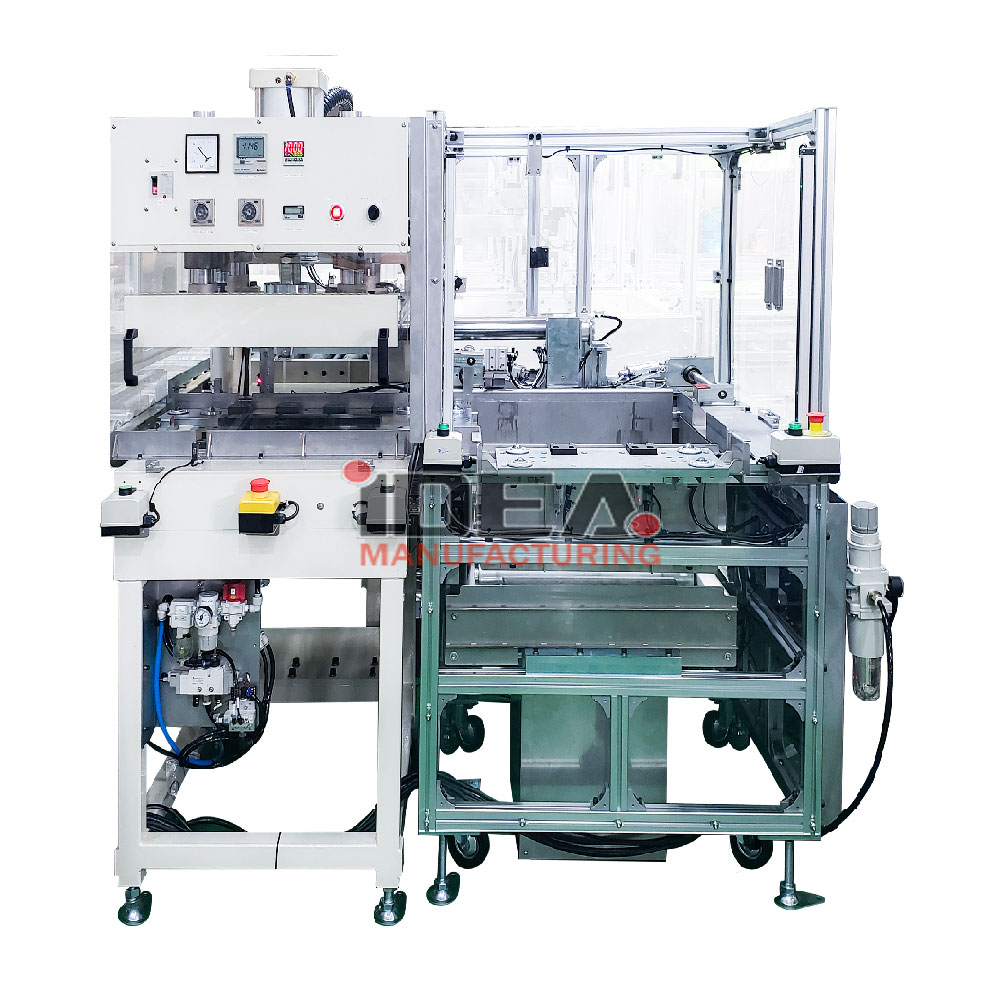

Automation involves the application of advanced technologies to control and monitor production processes with minimal human intervention. In machine manufacturing, this translates to the use of robotics, computerized control systems, and intelligent sensors to perform tasks such as material handling, assembly, quality inspection, and packaging.

By streamlining repetitive and labor-intensive operations, automation significantly boosts the precision and speed of production lines while reducing operational costs. It also enables manufacturers to maintain consistent product quality and quickly scale operations based on market demand.

Key Benefits of Automation for Production Lines

Adopting automated systems in manufacturing brings a multitude of benefits that drive industrial improvement:

- Increased Efficiency: Automated systems work continuously without fatigue, optimizing production uptime and throughput.

- Enhanced Precision: Robotics and control systems ensure high accuracy and repeatability in complex manufacturing tasks.

- Reduced Human Error: Automation minimizes the impact of manual handling mistakes, especially in high-volume or high-risk processes.

- Improved Safety: Replacing manual labor in hazardous environments keeps workers safe while increasing operational reliability.

- Cost Savings: Long-term investment in automation results in lower labor costs, reduced waste, and decreased downtime.

Emerging Trends Driving Industrial Improvement

As technology advances, several automation trends are shaping the future of machine manufacturing:

- Smart Manufacturing (Industry 4.0): Integration of IoT devices and cloud-based analytics allows real-time monitoring, predictive maintenance, and decision-making optimization across the factory floor.

- AI and Machine Learning: AI enables self-learning systems that improve performance over time, identifying patterns and optimizing processes with minimal human input.

- Collaborative Robots (Cobots): These robots work safely alongside humans, assisting in tasks that require flexibility and real-time decision-making.

- Flexible Automation: Modular and reconfigurable systems allow manufacturers to adapt quickly to new product lines or changing customer requirements.

Companies such as Che Tao May IDEA are at the forefront of deploying these technologies, helping industries transition toward smarter, more agile manufacturing environments.

Custom Automation and design: Tailored for Every Need

Not all automation solutions are one-size-fits-all. Customized machine design plays a critical role in implementing effective automation. Through machine design and drafting services, businesses can develop specialized equipment tailored to their production workflows.

Automation in this context isn’t just about upgrading machinery—it’s about reengineering entire production lines for peak efficiency and future scalability. This strategy ensures maximum ROI while keeping companies prepared for technological evolution and demand shifts.

Partnering With Experts for Scalable Success

For manufacturers ready to embrace automation, working with experienced solution providers is key. Whether it’s integrating sensors, PLCs, or designing fully automated production lines, expert partners bring the technical know-how and industry insights necessary for successful implementation.

Platforms like IDEA Tech Mart offer innovative components and automation tools for industrial applications, enabling seamless technology adoption across diverse sectors.

To explore how automation can elevate your manufacturing capabilities, engage with a proven leader like IDEA Group. From conceptual design to turnkey automation systems, we deliver tailored solutions that power industrial improvement and streamline production lines efficiently from start to finish.

Embrace the future of manufacturing—integrate automation, optimize your production lines, and drive lasting industrial improvement with IDEA Group. Contact us today to collaborate on your next automation project.